Fitech Material(s), making the real difference

This product was successfully added to cart!

High Purity Titanium Carbide (TiCN) Powder

Out of Stock

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Nano Hydride more than 3 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy nano composites, metal nanoparticles, alloy nanoparticles, oxide nanoparticles, rare earth oxide nanoparticles, or look for price quotation, please contact info@fitechem.com

Specification (% )

English name: Titanium carbonitride

CAS: 12654-86-3

MDL: MFCD01868685

Molecular formula: TiCN

Molecular weight: 121.75

Melting point: 2900℃

Density: 5.08 g/mL at 25 °C(lit.)

Hardness (HV) : 34GPaI density 4.52

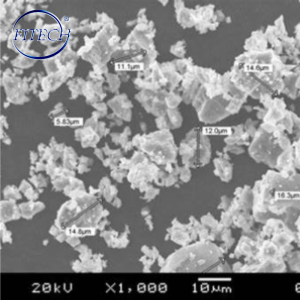

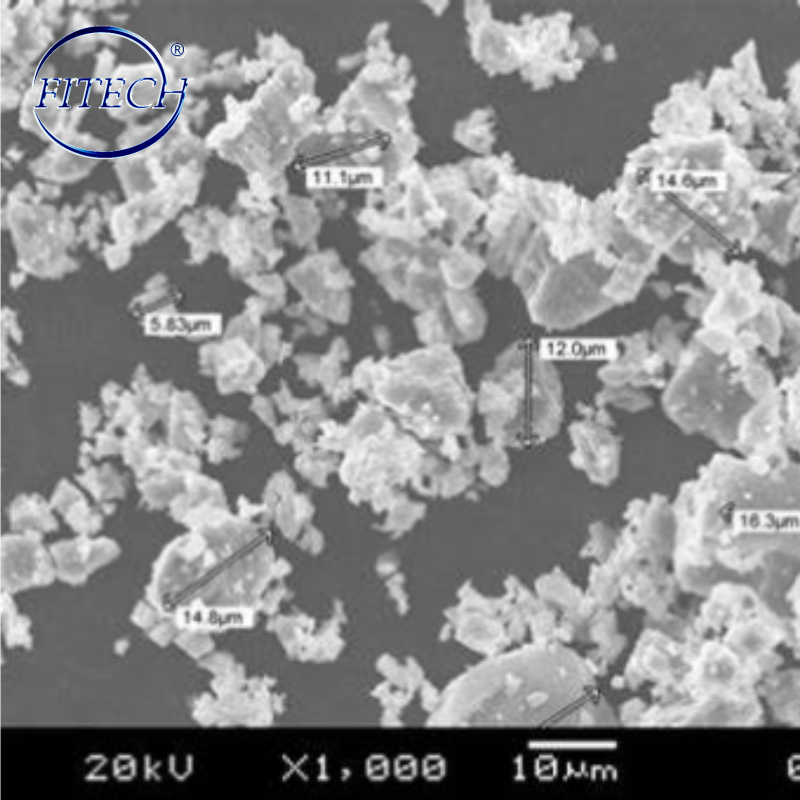

Properties: Gray or gray black powder, with hexagonal crystal structure, with low internal stress, high toughness, good lubricity, high hardness, wear resistance and other characteristics, suitable for occasions requiring lower friction coefficient and high hardness.

Applications

Application

1Ti(C, N) fund is a ceramic tool

Ti(C, N) foundation ceramics are a very important structural material, and the tools prepared with them are compared with WC-based cemented carbide.

The processing shows higher red hardness, similar strength, lower corrosion, thermal conductivity and friction coefficient, and has a better

High life or in the case of the same life can use a higher cutting speed, the workpiece to be machined has a better surface finish

Degree. It is understood that Japan's Ti(C, N) fund ceramic tool materials have accounted for more than 30% of all its tool materials market share.

2Ti(C, N) is a ceramic coating

Ti(C, N) foundation ceramics can be made into wear-resistant coatings and mold materials. Ti(C, N) coating has excellent mechanical properties

Tribological properties,

As a hard wear-resistant coating, it has been widely used in cutting tools, drills and molds, and has broad application prospects. Its control

The main preparation processes are plasma chemical vapor deposition, middle temperature chemical vapor deposition and traditional CVD method. Ti(C, N)

Compared with die steel, it has the advantages of no phase change, high temperature resistance, low friction coefficient and good adhesion resistance

With certain strength and toughness, it is a mold material with great potential for development.

3 Multiphase ceramic materials

Ti(C, N) can be combined with other ceramics to form composite materials, such as Ti(C, N)/Al2O3, Ti(C, N)/SiC,

Ti(C, N)/Si3N4,

Ti(C, N)/TiB2 and other multiphase ceramic materials, Ti(C, N) as the reinforcement can improve the strength and fracture toughness of the material.

It can also improve electrical conductivity.

4 Refractory materials

The addition of non-oxides to refractory materials will bring some excellent properties. Studies have shown that the presence of titanium carbonitride can be obvious

Improve the performance of refractory materials.

5 Synthesis of Ti(C, N) whisker

Exhibition Show

Packing & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Out of Stock