Fitech Material(s), making the real difference

This product was successfully added to cart!

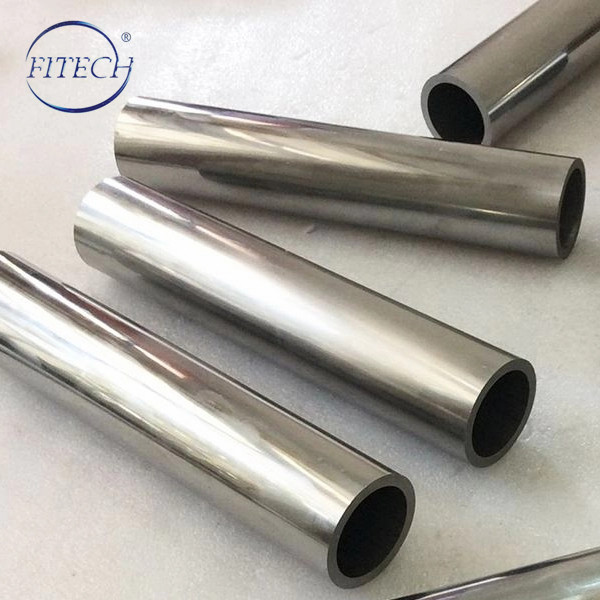

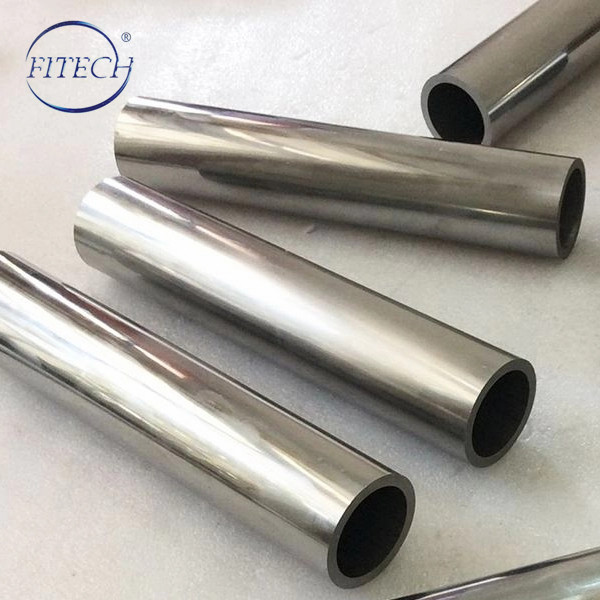

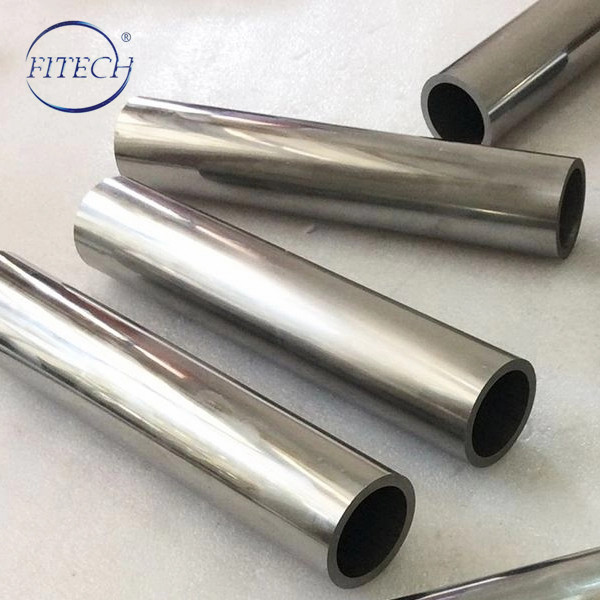

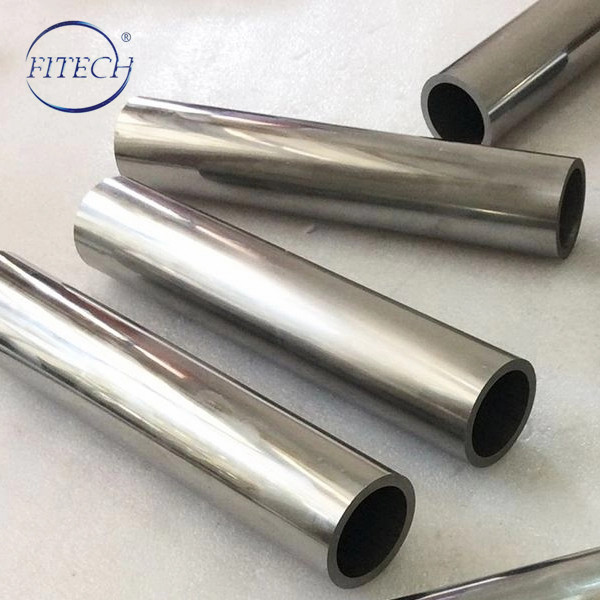

Tantalum Tube / Pipe

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd specializes in Tantalum Materials more than 10 years, with rich experience, high quality, and competitive price. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Non-ferrous, Metallurgy, Chemical Raw Materials or look for price quotation, or look for price quotation, please contact info@fitechem.com.

Specification (% )

Product Description

Tantalum Tube / Pipe

Tantalum Tube / Pipe processing technology and characteristics

There are two methods to process Tantalum Tube / Pipe: one is to produce seamless tube by extruding tube blank, and the other is to produce welded tube by drawing process after inert gas Tungsten arc welding.

Applications of Tantalum Tube / Pipe

Tantalum and Tantalum alloy tubes / pipes are commonly used in chemical industry, atomic energy and aerospace field.

Tantalum and Tantalum alloy tube / pipe (such as Ta-2.5W Tube, Ta-10W Tube, Ta-40Nb Tube, etc.) are more resistant to high temperature and mineral acid corrosion than many other materials. Tantalum and Tantalum alloy tubes are mainly used to manufacture reaction vessels, heat exchangers, pipes and thermocouple pipes for chemical processes.

| Advantage | Disadvantage | Description | |

| Welded Tube | 1.The wall thickness is uniform, and the inner surface quality is excellent2.High production efficiency and low cost3.Easy to produce large diameter tube 4.Product quality is easy to control |

1.Flexibility is poor, not suitable for producingvariety specifications and small batch products 2.Welds are often the weak links 3.Weld cleaning is difficult 4.Ovality is not easy to control 5.High precision is required for the used strip size |

Generally suitable for large-scaleproduction |

| Seamless Tube | 1.Can produce small size tube and capillary tube 2.Flexibility, suitable for small-scale production, more specifications 3.All parts of the tube have uniform performance |

1.The uniformity of the wall thickness is difficult to control 2.Long production cycle and low yield 3.Complex equipment and large investment 4.Difficult to produce large diameter pipes |

Generally suitable for the production of small quantitiesof many specifications of products |

Applications

Application:

Metallurgy, Industrial, Electronic, Medical,etc

Our Tantalum Sheet / Plate products

Our main Tantalum Plate products include pure Tantalum Plate, Ta-10W Sheet, Ta-2.5W Sheet, Tantalum Niobium alloy sheet, etc.

All Western Alloys' Tantalum Sheet / Plate products comply with ASTM standards, such as ASTM B708, ASTM F560, etc.

Tantalum Sheet / Plate applications

Tantalum Sheet and Tantalum Plate can be used in metallurgical industry to make heating parts, heat insulation parts and charging apparatus of vacuum high temperature furnace.

Such as the heating part of heater, bracket, heat insulation screen, crucible, etc.

Tantalum Sheet and Tantalum Plate can also be used in chemical, medical and aerospace industries.

Exhibition Show

Packing & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.