The strength, compactness, surface smoothness and particle size of coarse aggregate of concrete are the main factors that affect the abrasion resistance of concrete.

Nanomaterials can not only fill micropores, but also have small particle size, large specific surface area and extremely high reactivity. The strength and compactness of concrete can be improved through these two functions to enhance its impact resistance

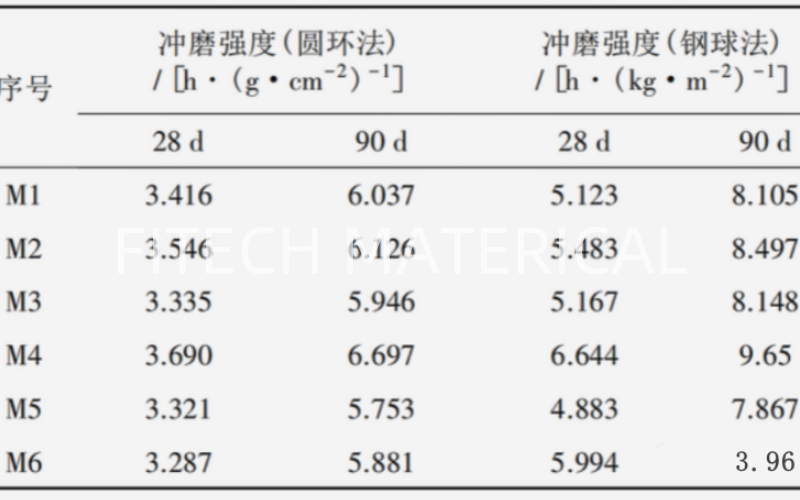

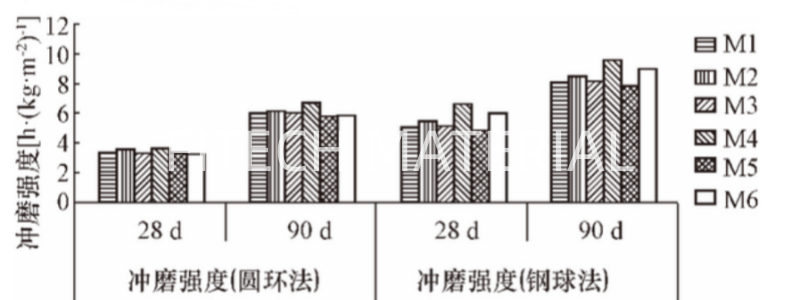

In order to study the influence of nano-silica on the impact wear of concrete, the impact wear strength of concrete was measured by ring method and steel ball method respectively. The results are shown in P1 and P2.

It can be seen from the experimental results that the addition of nanomaterials can improve the wear resistance of concrete, but excessive nanomaterials will reduce the wear resistance. The appropriate amount of nanomaterial has excellent reactivity, and the calcium hydroxide in cement can form hydrated calcium silicate gel. The nano-silica particles are small and play a role in filling the void of cement slurry, and the combination of the two can jointly improve the impact wear resistance of concrete. Due to the large specific surface area of excessive nanomaterials, their huge water demand will absorb excessive mixing water, resulting in a decrease in the actual water-binder ratio and poor hydration of cement particles, but reduce the impact wear resistance of concrete.

Therefore, nanomaterials have more advantages than silica powder, and their smaller particle size can fill the void more tightly, and their larger activity is also more conducive to the reaction with cement hydration intermediates.

Nanomaterials can effectively improve the abrasion resistance of concrete and contribute to the strength of concrete. However, the huge specific surface area of nanomaterials causes a large water demand, so it is necessary to select the variety and dosage of nanomaterials reasonably. The shrinkage of concrete increases. In the future, the use of recycled aggregate to prepare recycled concrete should consider the size of the mix, the amount of various materials, as far as possible to reduce the shrinkage rate, increase the strength and performance of recycled concrete.

Erosion resistance. Some relevant tests have found that the sulfate erosion resistance of recycled concrete can be basically the same as that of ordinary concrete, but the condition is that the replacement rate of recycled aggregate is less than 30%. With the increase of recycled aggregate substitution rate, the sulfate resistance of recycled concrete decreases, but the difference is not significant.

Durability. Comprehensive scientific research has found that the durability of concrete is determined by its own strength and hardness. Due to the inevitable defects of recycled aggregate, the higher the amount of recycled aggregate added to the concrete, the worse the durability will be. When the replacement rate is less than 50%, there is little difference with the wear resistance depth of ordinary concrete, when the replacement rate is 100%, the wear resistance depth of ordinary concrete is increased by 34%

Freeze-thaw resistance. As for the freeze-thaw resistance of recycled concrete, it is found that the freeze-thaw resistance of recycled concrete is better than that of open concrete, and some studies have found that the freeze-thaw resistance of recycled concrete is worse than that of ordinary concrete.

Post time: Mar-05-2024