Nano-silica is non-toxic, tasteless, pollution-free, small particle size, large specific surface area, there are a lot of unsaturated bonds and different bonding states of hydroxyl groups on the surface, added to a large number of materials, will make the original material properties have a very significant change. The nano silica dispersion supplied by our company has good adhesive property, high temperature resistance, film forming property, gel property and charge property, and can be widely used in various industries.

- Function Introduction:

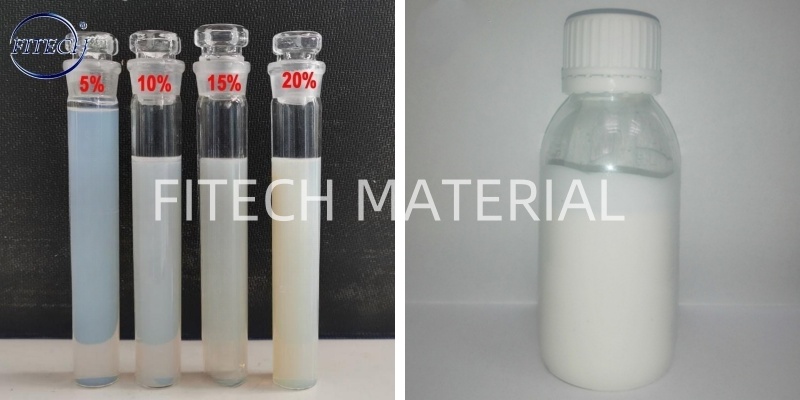

1. The nano silica solution produced by our company has acidic, neutral and alkaline, and uses products of similar pH types in different environments.

2. Ultrafine sodium-rice SiO2 is in the range of 8~15nm, has high activity and good permeability, and can act on the edge of the metal surface treatment process such as electroplating and fill the position of ultra-fine holes.

3. Nano-silica can act on the micropore in a very short time (30 seconds to 60 seconds), after the appropriate temperature lt; 100℃) after baking and drying, it will react with the base material and surrounding auxiliary materials.

- Action range:

Electroplating, painting and other processes can not ensure the corner of the device. Under the microscope, the workpiece after electroplating has a lot of ultra-fine holes (micron or even nanometer scale) exposed to the air, and these unprotected parts will be the source of electrochemical reactions that lead to rust of the metal workpiece. And nanomaterials act on these positions where electroplating, painting and other processes do not work.

- Application method(for reference):

1. Use in passivation solution: In the electroplating process, add 10%~30% of the product to the passivation solution product, and then use it according to the normal process after stirring.

2. Directly used as a sealing agent: dilute the product 4 to 5 times with pure water, and then immerse the device directly in the pure water solution after electroplating, passivation, washing and other processes, soak for about 30 seconds, take out and dry.

3. The product can be directly added to the concentrated liquid of the original passivation liquid and sealing agent to improve the performance of the product. It can also be added directly to the working fluid in the plating process for use.

Packing: 1kg/ bottle 25kg/ barrel

Related link:

https://www.topfitech.com/colloidal-silica-dioxide-for-investment-casting-nano-silica-sol-product/

Post time: Feb-27-2024