Fitech Material(s), making the real difference

This product was successfully added to cart!

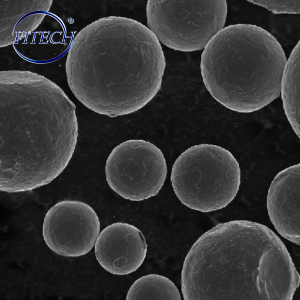

Factory Supply 420 Die Steel Powder Ferro-Based Alloy 3D Printing Powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

The use of 420 die steel quenching and tempering state (hardness 48-54HRC), in order to meet the long-term work or the number of parts up to 1 million or more life requirements, the more suitable use method should be quenching low temperature tempering treatment. Quenching is first heated to 1000-1050ºC to hold heat for a certain time (calculated at 30 minutes /25mm), and then quenched into the oil to cool to 50-100ºC and immediately temper treatment to prevent cracking. Tempering at 200ºC (at least 4 hours) hardness can reach more than 48HRC, with better polishing and better corrosion resistance.

| Main products | 420 | |||

| mobility | 15-53μm | ≤18s/50g | ||

| Bulk density | ≥4.10g/cm3 | |||

| Oxygen content | ≤300ppm | |||

| Nitrogen content | ≤300ppm | |||

| Mechanical property | Compressive strength /MPa 1750±50Yield strength /MPa 1450±50

Elongation /% 6±2 |

|||

Excellent corrosion resistance; Excellent optical rotation; Excellent wear resistance; Excellent machinability; Excellent stability during quenching.

Because the cooling channel of the mold is not affected by corrosion (unlike ordinary die steel), the heat conduction characteristics and cooling efficiency remain stable during the life of the mold, ensuring the constant forming time of the mold.

Applications

Aerospace

Mold making

Suitable for all kinds of plastic products mold, more suitable for mold with special requirements.

Suitable for making mold in weak acid and humid environment.

Suitable for transparent plastic products such as CD, optical instruments.

Suitable for high polishing mirror mold.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.