Fitech Material(s), making the real difference

This product was successfully added to cart!

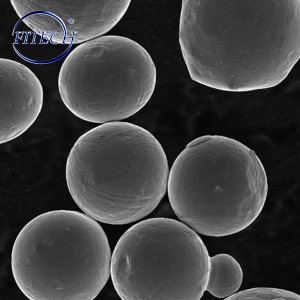

Nickel-Base Superalloy Gh3536 (HX) 3D Printing Spherical Powder

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Anhui Fitech Material Co.,Ltd has successfully certified by ISO 14001:2015 environmental management system,ISO 9001:2015 quality management system and ISO 45001 occupational health and safety certification. As a professional manufacturer and supplier, we have our own professional technology team to meet any of your requirements in quality and technology. If you want to buy Cobalt base alloy powder, Nickel base alloy powder, Ferro base alloy powder, Titanium base alloy powder, other 3D printing powder, or look for price quotation, please contact judy@fitechem.com

Features

GH3536 alloy is a kind of nickel-based superalloy with high iron content strengthened by solid solution of chromium and molybdenum.

| Main chemical composition | Oxygen and nitrogen content/Mechanical properties (Heat treatment) | ||

| C:0.05-0.15 | Cr:20.5-23.0 | Oxygen content:≤500ppm | Nitrogen content:≤100ppm |

| Ni:surplus | Co:0.5-2.5 | Yield strength /MPa:325±10 | Compressive Strength /MPa:720±20 |

| Mo:8.0-10.0 | Al:≤0.50 | Elongation /%:50±3 | |

| Ti:≤0.15 | W:0.2-1.0 | Yield strength (900ºC)/MPa:165±5 | Compressive Strength (900ºC)/MPa:220±10 |

| Fe:17.0-20.0 | Elongation (900ºC)/%:30±4 | ||

It has good oxidation resistance and corrosion resistance, medium to long lasting and creep strength below 900ºC, and good formability and weldability in cold and hot working. It is suitable for the manufacture of combustion chamber parts and other high temperature parts of aeroengines. It can be used for a long time below 900ºC and the short-term working temperature can reach 1080ºC. Alloys that can withstand a certain stress and have oxidation or corrosion resistance at a high temperature of 600~1200ºC.

Applications

Aircraft nozzles, chemical industry, petroleum industry, nuclear energy industry.

Superalloys are mainly used in the manufacture of high-temperature components such as turbine blades, guide blades, turbine discs, high-pressure compressor discs and combustion chambers for aviation, naval and industrial gas turbines. It is also used in the manufacture of space vehicles, rocket engines, nuclear reactors, petrochemical equipment and energy conversion devices such as coal conversion.

Industrial and aerospace steam turbines (combustion chambers, rectifiers, structural covers);

Industrial furnace components, support rolls, grid plates, ribbons and radiation tubes;

Spiral tubes in petrochemical furnaces;

High temperature gas cooling nuclear reactors.

A N H U I F I T E C H M A T E R I A L C O . , L T D

National Innovation Industrial Base Huguang Road, Shushan District, Hefei, Anhui, China

Exhibition Show

Factory & Payment

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.