Fitech Material(s), making the real difference

This product was successfully added to cart!

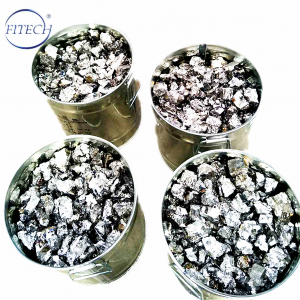

Used in Steel Making 14~20% Ferro Boron

-

Quality First

-

Competitive Price

-

First-class Production Line

-

Factory Origin

-

Customized Services

Basic Information

Alloy of boron and iron. According to carbon content, boro-iron (boron content: 5-25%) can be divided into low carbon (C≤0.05% ~ 0.1%,9% ~ 25%B) and medium carbon (C≤2.5%,4% ~ 19%B). Iron boron is a strong deoxidizer and boron addition agent in steelmaking. The greatest role of boron in steel is that only a very small amount of it can significantly improve the hardenability and replace a large number of alloying elements. In addition, it can also improve mechanical properties, cold deformation properties, welding properties and high temperature properties.

Mainly used in steel and cast iron. Used for alloy structural steel, spring steel, low alloy high strength steel, heat resistant steel, stainless steel, etc. Boron can improve toughness and wear resistance in cast iron, and is widely used in the manufacture of automobile, tractor and machine tool.

| Product name | Ferro Boron |

| Brand name | FITECH |

| Melting Point | 1400-1550ºC |

| Appearance | Silver Metal Lump |

| Elements | Fe; B; |

| Purity | 14~20% |

| Packing | 1000kg jumbo bag packing |

Applications

Adding 0.07%B to steel can significantly improve the hardenability of steel. Boron added to 18%Cr, 8%Ni stainless steel after treatment can make precipitation hardening, improve high temperature strength and hardness. Boron in cast iron will affect the graphitization, thus increasing the depth of the crack to make it hard and wear resistant. Adding 0.001% ~ 0.005% boron to malleable iron is beneficial to forming spheroidal ink and improving its distribution. Low aluminum and low carbon boron iron are the main raw materials of amorphous alloys.

Packing

Packing: 1000kg jumbo bag packing

Loading: 20~20MT per 1×20'FCL

Exhibition Show

Packing & Transportation

FAQs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.